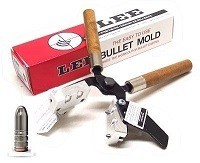

LEE MOULD C457-500-F DBL CAVITY

$77.00

Product Information

Lee Bullet Molds are a great choice for reloaders looking for a quality mold at an affordable price. Lee machines their mold blocks from aluminum making them rust resistant. Aluminum molds heat up and cool down faster than iron or steel molds and good bullets can usually be produced only after a few casts. In addition, aluminum blocks are one-third the weight of iron or steel mold blocks offering the bullet caster less fatigue during extended casting sessions. To ensure the best possible bullets, mold block halves are CNC machined for unmatched roundness and size control. Weights given are Lee’s weights with suggested alloy; actual weight may vary due to the alloy mixture used.

A note from Lee Precision on their bullet molds:

Lee Precision does not recommend the use of any spray type mold release products in their bullet molds. The use of such products may result in a build-up of the release product in the bullet mold cavity, reducing the diameter of the bullets cast from the treated mold. Instead, Lee Precision recommends smoking the mold with a wooden match, beeswax candle or a butane lighter as described in their provided bullet mold instructions.

2 in stock

Product Information

Lee Bullet Molds are a great choice for reloaders looking for a quality mold at an affordable price. Lee machines their mold blocks from aluminum making them rust resistant. Aluminum molds heat up and cool down faster than iron or steel molds and good bullets can usually be produced only after a few casts. In addition, aluminum blocks are one-third the weight of iron or steel mold blocks offering the bullet caster less fatigue during extended casting sessions. To ensure the best possible bullets, mold block halves are CNC machined for unmatched roundness and size control. Weights given are Lee’s weights with suggested alloy; actual weight may vary due to the alloy mixture used.

A note from Lee Precision on their bullet molds:

Lee Precision does not recommend the use of any spray type mold release products in their bullet molds. The use of such products may result in a build-up of the release product in the bullet mold cavity, reducing the diameter of the bullets cast from the treated mold. Instead, Lee Precision recommends smoking the mold with a wooden match, beeswax candle or a butane lighter as described in their provided bullet mold instructions.

| Weight | 1.2 lbs |

|---|

Related products

LEE MOULD (.440 Diameter) 128gr Round Ball

LEE MOULD 309-120-R DBL CAVITY

Product Information

LEE MOULD 358-158-RF SIX CAVITY

Product Information

Designed for volume production, the Lee 6-Cavity Bullet Mold blocks are machined from commercial quality aluminum and feature steel bushing and alignment pins. Lee mold blocks are machined from aluminum blocks making them rust resistant. Aluminum molds heat up and cool down faster than iron or steel molds so good bullets can usually be produced after only a few casts. In addition, they are one-third the weight of iron or steel mold blocks for less fatigue during extended casting sessions. To ensure the best possible bullets, mold block halves are CNC machined for unmatched roundness and size control. Lee 6-Cavity molds come with a cam operated, hard-anodized sprue plate which is held tightly with tempered spring washers at each end. Weights given are Lee's weights with suggested alloy; actual weight may vary due to alloy mixture used. Handles ARE NOT included (#90005). Material: Machined Aluminum Mold Blocks and Hard Anodized Sprue Plate Cavities: 6 Notes: Handles to open and shut the mold are sold separately item# 117-892 A note from Lee Precision on their bullet molds: Lee Precision does not recommend the use of any spray type mold release products in their bullet molds. The use of such products may result in a build-up of the release product in the bullet mold cavity, reducing the diameter of the bullets cast from the treated mold. Instead, Lee Precision recommends smoking the mold with a wooden match, beeswax candle or a butane lighter as described in their provided bullet mold instructions.LEE MOULD 454-298-M IMPROVED MINIE

Product Information

LEE MOULD 459-500-3R DOUBLE CAVITY

Product Information

Lee mold blocks are made from aluminum because of the exceptional molding qualities. The mold cavities are lathe bored for unmatched roundness and size control. Lee single cavity molds include handles and sprue plate.

This Lee Double Cavity Mold produces a .459 diameter 500 grain round nose bullet suitable for 45-70 Caliber Rifle.